Sunday, February 28, 2010

#007 01 Dr. Bank's Office - Casting the Walls

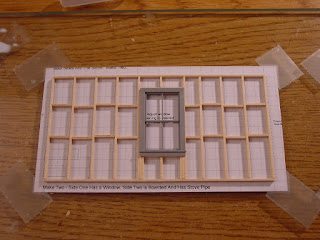

The framing is good. Not perfect, but acceptable for what I'm modeling. Looks like Scott needs to get new glasses, so I'll go see the doc next week.

What I want to do is to make molds of both sides so that I can produce more of these and use them as bunk houses. Since the frame takes alot of long and tedious work, we'll just cast them in plaster. We'll start with two sheets of .020 acetate since it was handy. You can use styrene or wood as well.

Next we remove the framing from the paper drawing. This is rather a pain in the but and I'm not sure I'll do this again. Next time I'll add a coat of wax paper.

There! All cleaned up and ready to be mounted to the mold frame.

Here is the acetate sheet. I like the clear material because it let's me see how well the master and casting dams are mounted, letting me check for gaps and leaks.

Using some 1/4" square basswood boards, I make a pinwheel dam. This is an easy way to build a dam that doesn't require a lot of accuracy in cutting and can be removed easily.

Done. Now I'll do the other one and let the glue dry. Note that Ailene's Tacky Glue was used liberally as wood and plastic don't always stick together. If the master is not fastened down properly it will float up into the silicone and be destroyed.

While our mold set dries, let's make some clap board. I'm using S scale 2" x 12" boards which come out to about a 1" x 9" board. The O scale 2 x 12 looked a little clunky, so I used this since I had it on hand. First I distressed the wood with a razor saw blade.

There is an exterior side and an interior side. Each has to be weathered differently. In order to keep track of sides I put a spot of red paint (or magic marker) on one end on one side.

Next I took a dull hobby knife and scored up the boards, even chopping some parts of the board away.

Damn! The Canadians beat the US in overtime. That was for the gold. Crap!

Here is where I "chunked" the board.

After I got through distressing the board, I gave it a light sanding to get rid of the fuzz.

Next I coated the exterior (red dot) side with Dr. Ben's Aged Driftwood Stain. This was done rather sloppily in order to get some randomness.

Then I weathered the interior side of the boards using Dr. Ben's Instant Age Stain. Again, I was sloppy and didn't make the wood too dark as it will be inside.

Once the boards were all weathered I placed them under a glass plate to dry and flatten out (the solvent in the stains will make them curl a bit.)

I sprayed the two masters with Testor's Dullcoat and let them dry. Later in the evening I came back and mixed up some Alumilite HS3 Silicone Mold Making Compound. This is a small kit that I keep around but often I buy it by the bucket.

You have to follow the directions carefully or it won't solidify. I'm kind of worried about this batch since the material is over a year old. I mixed 5 oz of white and a 1/2 oz of red activator.

The batch was mixed THOROUGHLY and air bubbles were allowed to escape.

I poured the silicone mold maker into the frames very slowly to help air bubbles escape We'll let both molds cure for 24-48 hours. This is a thin mold, so 24 should be enough. We'll take the wood frame out and make a casting to test the mold.

That's all for now!

Labels:

01 Dr Banks Office,

mold making,

Weathering

Thursday, February 25, 2010

#001 06 Dr. Bank's Office - Inside the Office

I've had a bad night with my little one and finally have her in bed. Jeez....what a night.

I'm too tired to model, so let's do some planning. All of the photos I collected are now in a binder and one thing I need to do is to come up with a list of details to put inside the Doctor's office. My plan is to scratchbuild most of them. We'll just look at each picture and write down what we see.

Dr.'s Office Contents - Uncut

The roll top desk will be a focal point, as will the exam table and curtain. I expect to make the lamps really work using fiber optics. Many of the details might have to be attached to the wall or floor before assembly.

Figures...

Finding a Doctor might be harder than I thought, at least the white coated kind. Naturally I checked out Arttista at http://www.arttista.com/ first. I also sent a note to my friend Alan Pollock at Fun & Games (The People People) to see if he has them. We'll see what they both come back with. Probably post it on the On30 Conspiracy Yahoo Group as well.

Blue Mountain contacted me off line, but they don't have a doctor. In fact, nobody seems to have a doctor! What's up with that? Ok, time to get out the carving tools and make a greenie. I hate carving figures, but this one is too key to the model. I need the practice anyway.

I'm too tired to model, so let's do some planning. All of the photos I collected are now in a binder and one thing I need to do is to come up with a list of details to put inside the Doctor's office. My plan is to scratchbuild most of them. We'll just look at each picture and write down what we see.

Dr.'s Office Contents - Uncut

- Eye chart

- Roll top desk

- Rolling chair

- Patient chair

- Exam table

- Glass cabinet for medical books

- Wall telephone box

- Magnifying glass

- Small stove

- Kettle

- Clock

- Skeleton on hanger

- Cabinet for tools - glass

- Cabinet for medicines - wood

- Doctor's bag

- Medicine bag

- Lunch basket

- Coat rack w/ hat & coat

- Jars with bandages, cotton balls, etc

- Oil lamp(s)

- Dental chair

- Medicine bottles

- Mortar & pestle

- Scales - balance

- Crutches

- Picture of Hippocrates

- Water bowl and towels for hand cleaning

- Patient

- Doctor Banks

- Balance scale for people weight

- Diploma in frame

- Candle

- Doctor's instruments

- Patient screen

- Whiskey

The roll top desk will be a focal point, as will the exam table and curtain. I expect to make the lamps really work using fiber optics. Many of the details might have to be attached to the wall or floor before assembly.

Figures...

Finding a Doctor might be harder than I thought, at least the white coated kind. Naturally I checked out Arttista at http://www.arttista.com/ first. I also sent a note to my friend Alan Pollock at Fun & Games (The People People) to see if he has them. We'll see what they both come back with. Probably post it on the On30 Conspiracy Yahoo Group as well.

Blue Mountain contacted me off line, but they don't have a doctor. In fact, nobody seems to have a doctor! What's up with that? Ok, time to get out the carving tools and make a greenie. I hate carving figures, but this one is too key to the model. I need the practice anyway.

Wednesday, February 24, 2010

#001 05 Dr. Bank's Office - Framing

I'm using two new tools on the workbench tonight. You can read my review here...

http://traintools.blogspot.com/

We're still framing the two long walls tonight. The new Chopper II should allow me to get better cuts than I was getting on the old unit. Let's see...

The right wall is now partially framed and drying. The smaller boards are much more neatly cut than before. You'll notice that the studs are not lining up with the diagram. I actually had a hard time cutting the fire break boards to the proper dimension and so they are a bit long. It won't matter though.

The left wall is a mirror image of the right.

Darryl Huffman uses a wider pair of tweezers than I normally use, so I grabbed a pair out of my toolbox and gave them a try tonight. I do like them and find that I can hold a small piece for a longer time without my fingers cramping up. Might switch.

Here is the left side with all the framing in place. It went together well, so let's test fit the Grandt Line Window.

The window fits greats and will only need a little shimming, as does the prototype.

The right side is now done, and the window hole is the same dimension as the other wall.

Yup, the window fits! Good! The wall framing is done. The next step is to add a guide board and stain some clap board!

http://traintools.blogspot.com/

We're still framing the two long walls tonight. The new Chopper II should allow me to get better cuts than I was getting on the old unit. Let's see...

The right wall is now partially framed and drying. The smaller boards are much more neatly cut than before. You'll notice that the studs are not lining up with the diagram. I actually had a hard time cutting the fire break boards to the proper dimension and so they are a bit long. It won't matter though.

The left wall is a mirror image of the right.

Darryl Huffman uses a wider pair of tweezers than I normally use, so I grabbed a pair out of my toolbox and gave them a try tonight. I do like them and find that I can hold a small piece for a longer time without my fingers cramping up. Might switch.

Here is the left side with all the framing in place. It went together well, so let's test fit the Grandt Line Window.

The window fits greats and will only need a little shimming, as does the prototype.

The right side is now done, and the window hole is the same dimension as the other wall.

Yup, the window fits! Good! The wall framing is done. The next step is to add a guide board and stain some clap board!

Tuesday, February 23, 2010

#001 04 Dr. Bank's Office - Starting Construction of Walls

Let's make some sawdust! I bought a small pack of Midwest Products Scale Lumber Stock #8018 .0416 x .0833 x 11" 15 pc bag for $2.99. This will get me started on framing the 2 x 4 walls. I had the Trainmaster Models Hobby Shop order some more for me. Projects like this eat up scale lumber!

Since I wanted to work along with Darryl Huffman's Scratchbuilding In Wood DVD, I decided to move my work bench upstairs to the office and work in front of the computer. Normally I wouldn't do this but Marie is VERY pregnant and I like being close by the bedroom as she gets tired late at night and might need me.

Unlike Darryl, I like to work on glass plates. He uses laminated MDF boards. To me, glass is easier to clean and it is heavy so it doesn't move much. I use a 2' section of 1/4" think edged glass that came from a store shelving unit. It's been with me for years. To clean it I just scrape it with a razor scraper and then clean with Clorox's 409 Glass Cleaner or acetone (for paint). Instead of turning the square of wood around like Darryl, I just slide the plate glass left or right to work on the next section.

Here I have taped two drawing sections to the glass, one for each wall.

Using my well-worn NWSL Chopper I cut out the top plates and the studs. My chopper is shot so I need a new one. The razor has dug a hole in the masonite base plate and the boards are breaking instead of slicing. One of these days I'll have an extra $250 and will buy a Caliber Cutter. In the mean time I'll head over to the hobby shop and buy another chopper to hold me over. This one is 20+ years old.

Following Darryl's instructions on the DVD playing on my computer, I put in the top and bottom plates, the side studs and then begin filling in the fire blocks and studs. Darryl didn't use scale 2x4's. He used strip wood, 1/16" x 1/8". I think either is fine, but this model is for judging and I want to get it as right as I can.

Since my daughter plays in the office, I'll have to be careful cleaning up at night. The glass plate and the sharp tools all go up on a very high shelf.

...stay tuned!

Since I wanted to work along with Darryl Huffman's Scratchbuilding In Wood DVD, I decided to move my work bench upstairs to the office and work in front of the computer. Normally I wouldn't do this but Marie is VERY pregnant and I like being close by the bedroom as she gets tired late at night and might need me.

Unlike Darryl, I like to work on glass plates. He uses laminated MDF boards. To me, glass is easier to clean and it is heavy so it doesn't move much. I use a 2' section of 1/4" think edged glass that came from a store shelving unit. It's been with me for years. To clean it I just scrape it with a razor scraper and then clean with Clorox's 409 Glass Cleaner or acetone (for paint). Instead of turning the square of wood around like Darryl, I just slide the plate glass left or right to work on the next section.

Here I have taped two drawing sections to the glass, one for each wall.

Using my well-worn NWSL Chopper I cut out the top plates and the studs. My chopper is shot so I need a new one. The razor has dug a hole in the masonite base plate and the boards are breaking instead of slicing. One of these days I'll have an extra $250 and will buy a Caliber Cutter. In the mean time I'll head over to the hobby shop and buy another chopper to hold me over. This one is 20+ years old.

Following Darryl's instructions on the DVD playing on my computer, I put in the top and bottom plates, the side studs and then begin filling in the fire blocks and studs. Darryl didn't use scale 2x4's. He used strip wood, 1/16" x 1/8". I think either is fine, but this model is for judging and I want to get it as right as I can.

Since my daughter plays in the office, I'll have to be careful cleaning up at night. The glass plate and the sharp tools all go up on a very high shelf.

...stay tuned!

Sunday, February 21, 2010

#001 03 Dr. Bank's Office - Drawings Complete

I finished up the drawings this morning in 3rd Plan It. Here are snapshots. Next, we'll need to buy some lumber and get busy!

As to NMRA AP scoring, I got my friend and NMRA SER Region AP Chairman Randall Watkins to pre-score this model. What? You haven't even built it. Well, yeah. But WHAT you are going to do, coupled with some assumptions, can yield a score! I always do this exercise just to make sure I am STARTING with a model that can win 87.5 points.

Per Randall Watkins:

RW

As to NMRA AP scoring, I got my friend and NMRA SER Region AP Chairman Randall Watkins to pre-score this model. What? You haven't even built it. Well, yeah. But WHAT you are going to do, coupled with some assumptions, can yield a score! I always do this exercise just to make sure I am STARTING with a model that can win 87.5 points.

Per Randall Watkins:

More that 87.5,

CONSTRUCTION: Simple Model to Very Complex or Difficult.

I would say Somewhat Complex and your workmanship would be Bery Good.

27 to 29 Points. (my score 28)

DETAIL Complexity of Detail, I would say Moderate Detail and Easy-to Add

10 to 11 Points. (my score 11)

CONFORMITY: Do you have photos and/or plans, if no plans or documentation

a maximum of only 15 points. Your will have plans, the model will be Largely

prototypical to Completely Prototypical.

20 to 22 Points (my score 21)

FINISH & LETTERING:

Complexity is from Simple to Complex, this model i would say Moderate,

Your finishing would be Good to Better .

16 to 18 Points. (my score 17)

SCRATCH-BUILDING: (The good Part) The Complexity of this model would be Moderate

and Completely Scratch built.

13 Points (my score 13)

I would score it 90 points.

Thanks, Randall! I scored it and got a 91, so we're in the ball park. Still not a lot of wiggle room, but judges usually score more flexibly than either I or Randall do. Actually, I'm a tough judge, but gladly took 88 points on a kit I built once.

Off to the basement to get cracking!

#001 02 Dr. Bank's Office - Make Drawing

Tonight I began the drawings for Dr. Bank's Office. First, I went searching on the internet for prototypes that matched Darryl Huffman's Miner's Bar. There were quite a few including a historical preservation Doctor's Office that is almost identical to it!

All in all about two dozen prototype outer photos and another dozen interior photos are in the files now. Yes, I am detailing the interior. It is a forefront model.

I made a few changes to the front of Darryl's building but the rest remains true to form. For the NMRA contest we'll call this freelancing, and I'll use the prototype photos to back up the construction practice.

The big question is can it make 87.5 points even if I do an awesome job due to the complexity category. I'm thinking board-by-board construction should get me there.

We'll begin construction in two weeks.

Your thoughts?

(Actually, I went and got the NMRA Judging Guidelines. If I do a really good job on the finish and the interior detail, I should score between 88-91. That will do!

Saturday, February 13, 2010

#001 01 Dr. Bank's Office - Found the Model

Doc Banks is the company physician. He always calls himself a physician instead of a doctor. Banks if from Philadelphia and worked with Hebard Lumber after he lost his practice due to a little gambling problem. Often, after hours, you can find the good Doctor engaged in a game of cards. Other times its hard to find ole doc Banks at all.

The doctor has his own office on Billy's Island, provided by the Cypress Company. Anyone that is associated with lumbering can go see him. Locals can even come in if they like, but they seldom do.

I've decided to build one of Darryl Huffman's "Miner's Bar" building for the doc. The big windows and the sign board will serve him nicely. We'll white wash it up for him and even put a caduceus on the sign.

The building is not too hard to build and if I make a mold of the interior structure I can rapidly reproduce these to make the logger's cabins. It is a very flexible structure and I'll detail the interior. Maybe I'll change the sign board a little, but the rest will work fine.

Darryl goes into great detail on how to build the structure in his dvd series Scratchbuilding In Wood. You can read my review of the 4 DVD series by clicking on the link.

Meanwhile, Doc Banks is over at the engine house trying to scare up a game for tonight.

The doctor has his own office on Billy's Island, provided by the Cypress Company. Anyone that is associated with lumbering can go see him. Locals can even come in if they like, but they seldom do.

I've decided to build one of Darryl Huffman's "Miner's Bar" building for the doc. The big windows and the sign board will serve him nicely. We'll white wash it up for him and even put a caduceus on the sign.

The building is not too hard to build and if I make a mold of the interior structure I can rapidly reproduce these to make the logger's cabins. It is a very flexible structure and I'll detail the interior. Maybe I'll change the sign board a little, but the rest will work fine.

Darryl goes into great detail on how to build the structure in his dvd series Scratchbuilding In Wood. You can read my review of the 4 DVD series by clicking on the link.

Meanwhile, Doc Banks is over at the engine house trying to scare up a game for tonight.

Sunday, February 7, 2010

The Hebard Cypress Saw Mill

Click on Photo to Enlarge

The Hebard Cypress Saw Mill is very unusual looking. Kind of modern in fact. It has been very hard to find photos of this mill. I intend to construct an O scale version for the layout.

Subscribe to:

Comments (Atom)